Welcome to Our online shop

'O' Ring Top of Cylinder Block.

BDK Race Engineering

MSRP:

Was:

Now:

£38.40

inc. VAT

MSRP:

Now:

£32.00

ex. VAT

(You save

)

- SKU:

- GT750-ORC

- Width:

- 15.00 (cm)

- Height:

- 15.00 (cm)

- Depth:

- 2.00 (cm)

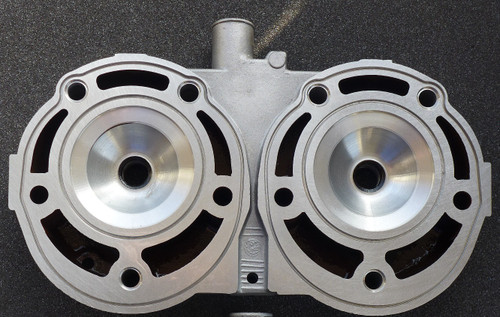

'O' Ring Top of Cylinder Block.

We tried various methods to seal the cylinder head face when the pressures are sufficient to make around 100bhp. Many reasons they failed, uneven bolt pattern, just not enough bolts etc etc. Eventually we sealed the head with 'O' Rings which has proved to be very successful. Down side is that there are many areas that need to be sealed, although the high pressure is only in the cylinders, it appeared stupid not do everything in one go. A lot of engines of this period used copper washers to seal water or oil, which means you have oil, or water in the case of the GT down the head studs, which is why after a few years they can be a little tricky to remove. The top of the block needs to be machined flat and then the 'O' ring groves machined into the block. There are 'O' rings around every stud or bolt, the water jacket and the combustion chambers. If we are lifting the block up with a spacer the correct amount can be machined off at the same time. If we are doing the head as well we machine dowel holes to locate the head and block together correctly.

This is for machining the top of the block flat, and machining the 'O'Ring Grooves.

Set of 'O' Ring Price.

Recommended

-

Cylinder Block Tuning

MSRP:Was:Now: £624.00 inc. VATMSRP:Now: £520.00 ex. VAT

Yamaha RD400 Head O ring Conversion

MSRP:Was:Now: £216.00 inc. VATMSRP:Now: £180.00 ex. VAT

Yamaha RD500 Head O ring Conversion

MSRP:Was:Now: £35.40 inc. VATMSRP:Now: £29.50 ex. VAT2 Stroke Head O-ring Service / Conversion

MSRP:Was:Now: £210.00 inc. VATMSRP:Now: £175.00 ex. VAT

Suzuki RGV125-Fun Head O ring Conversion

MSRP:Was:Now: £210.00 inc. VATMSRP:Now: £175.00 ex. VAT