Welcome to Our online shop

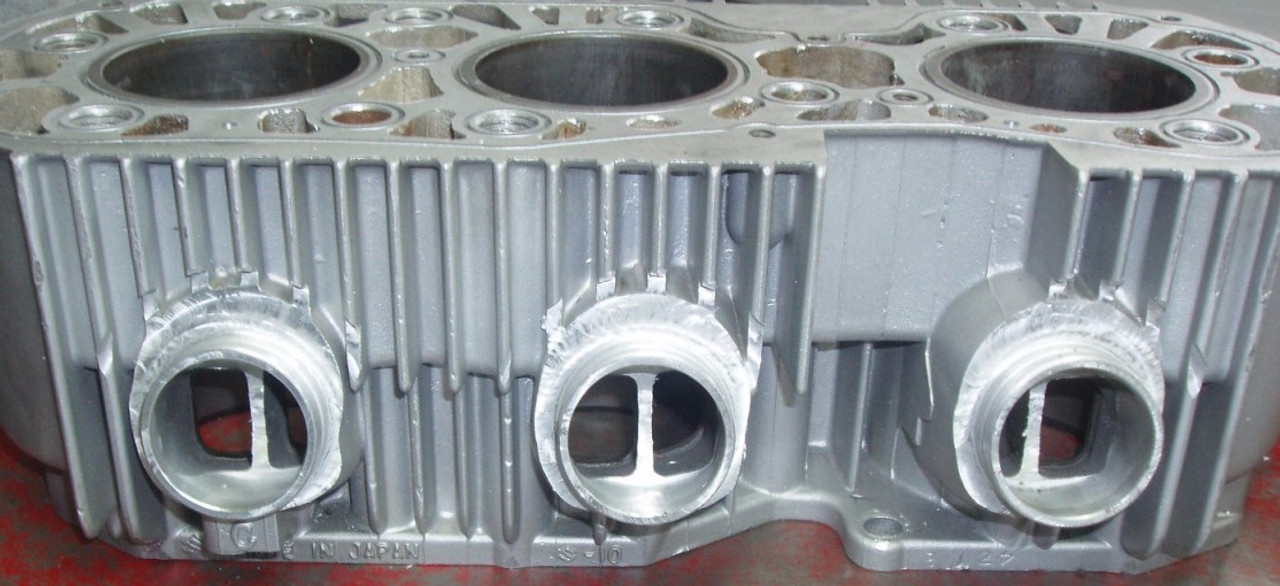

Inlet Port + Carburettor Stub Machining - GT750

BDK Race Engineering

MSRP:

Was:

Now:

£432.00

inc. VAT

MSRP:

Now:

£360.00

ex. VAT

(You save

)

- SKU:

- IP+CSM

Tipping the inlet port and opening out the inlet to suit the choice of carburettor.

To efficiently get the fresh charge into the cylinder it needs to be as straight a path as possible, without any significant changes to cross sectional area, other than taper from the carburettor to the port. We remachine the standard block after building the stub up with weld to take the inlet rubber. This depends on carburettor type and size. We machine the stub and port from a solid cad model. Like this, although we cannot get all the way to the liner, we can ensure the cross sectional area change is linear over the length of the port and as straight as possible.

This is for welding and machining the inlet stub and port including the bridge. This does not go all the way to the liner, it is about 70mm down from the stub. To take the rest of the port out to the correct size + shape, and to match it to the machined area is done by hand and covered under cylinder porting.

Recommended

-

Gasket set complete GT750

MSRP:Was:Now: £67.20 inc. VATMSRP:Now: £56.00 ex. VAT

Crank seal kit GT750

MSRP:Was:Now: £99.00 inc. VATMSRP:Now: £82.50 ex. VAT

Suzuki Gt750 Quality Head Gasket

MSRP:Was:Now: £36.00 inc. VATMSRP:Now: £30.00 ex. VAT

Suzuki GT750 Small End Thrust Shims

MSRP:Was:Now: £7.14 inc. VATMSRP:Now: £5.95 ex. VAT